Energy management

Differential pressure transducer for determining air consumption in a wide range of industries

The global energy transition and the increasing demand for companies to operate more sustainably are making energy management a key issue for companies in all sectors. The need to save energy goes beyond purely economic interests and encompasses ecological, social and legal issues.

Energy management aims to identify and exploit potential energy savings. To begin with, the energy flows and energy sources in the company are recorded and analyzed. On this basis, suggestions for improvement are developed, their cost-effectiveness checked and finally implemented. In order to ensure a sustainable improvement in energy efficiency, companies formulate a comprehensive energy policy, set energy targets, draw up action plans and monitor the achievement of targets using key performance indicators. Energy management also influences organizational and technical processes as well as employee behaviour. For example, responsibilities for energy-related tasks are determined, communication channels are defined and the necessary staff competencies are ensured.

Differential pressure transducer for filter monitoring

In industrial processes, the treatment of process air for the ventilation and air conditioning of rooms is a significant primary energy consumer. In order to develop targeted energy-saving measures, it is necessary to record consumption volumes according to individual consumers.

By using differential pressure transmitters in combination with differential pressure transducers, the volume can be precisely determined and allocated to the individual consumers. This information provides valuable information on possible savings potential.

Pressure monitoring in air filters

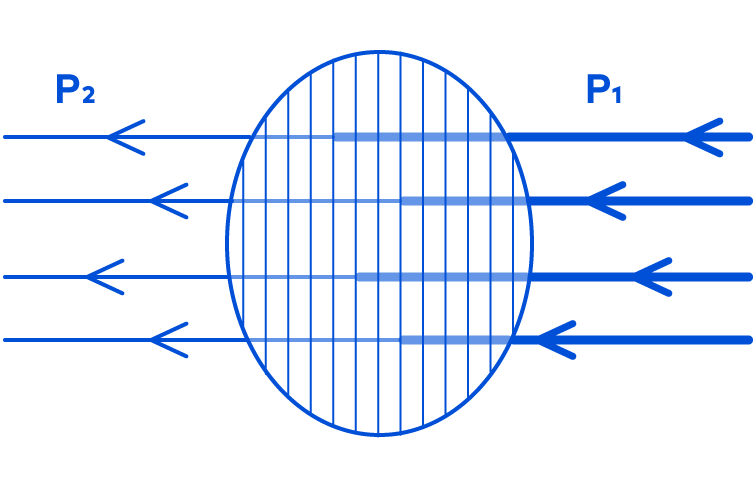

Differential pressure transmitters can be used to measure the pressure difference before and after air filters in HVAC systems. An increase in differential pressure indicates that the filter is becoming increasingly clogged. By detecting filter clogging at an early stage, maintenance measures can be initiated in good time and the filters replaced before the efficiency of the system suffers.

A clean filter ensures efficient operation of the ventilation system, which leads to a significant reduction in energy consumption. Regular monitoring of the filters not only offers benefits in terms of operating costs, but also helps to improve air quality and meet environmental standards.

Air pressure control in ducts

In large buildings, differential pressure measurement can be used to monitor and regulate the pressure in ventilation ducts. Precise control of ventilation air volumes can reduce the need for additional heating or cooling systems. This helps to reduce energy consumption as less energy is required to reach and maintain the desired temperatures.

Energy management in data centers

How important are data centers in our world?

Data centers are the foundation of digitalization. They enable the smooth operation of smartphones, industrial plants, transport infrastructure and communication. As the digital transformation progresses, the need for high-performance data centers is growing. However, this progress goes hand in hand with increasing energy consumption, which has a negative impact on the environment and climate. Data centers already accounted for around 1 to 1.5 percent of total electricity consumption worldwide in 2022 - and this proportion will continue to rise as digitalization progresses. In addition to IT systems, the greatest energy consumption is caused by cooling and infrastructure.

The topic of energy efficiency in data centers is therefore playing an increasingly central role - also in the economy. Companies must increasingly address the energy consumption of their data centers in order to reduce their ecological footprint. The Energy Efficiency Improvement Act (EnEfG), which was published on 18.11.2023, has dedicated an entire section to data centers. Technologies such as energy-efficient hardware and software, heat recovery and intelligent measurement and control systems offer promising approaches. In addition, certifications such as the Eco-Management and Audit Scheme (EMAS) or the Blue Angel can provide evidence of environmentally friendly operation and create incentives for more sustainable solutions.

Extremely precise measurement technology is required when planning and optimizing data centers. Even the smallest measurement errors or inaccuracies can significantly increase operating costs. Data centers are usually unmanned or have only a very small number of staff, so trouble-free operation must be ensured at all times. The maximum permissible annual downtime is 0.001%, which corresponds to approximately 5 minutes.

What approaches are there to increase efficiency?

Cooling: Data centers generate a considerable amount of heat from their servers. Effective cooling is required to dissipate this heat and regulate operating temperatures. Pressure differences are used to control the air flows required to cool the servers. Positive pressure ensures that cool air is directed into the server rooms, while allowing the warm air to be extracted.

Air circulation: To ensure optimum cooling, it is important that the air is circulated in a targeted manner. The differential pressure helps to precisely control this air circulation. If the pressure is too high or too low, this can lead to inefficient cooling conditions, which increases energy consumption.

Spatial arrangement: The use of cold and hot aisles has become established. Servers are arranged in special rows to separate cold air and warm exhaust air. The differential pressure between these zones must be monitored to ensure that the cooling works efficiently.

Solutions for filter monitoring

Standard transmitter

for basic applications

With our economical PS 17 and PS 27 series differential pressure sensors, the condition and degree of contamination of filter systems, for example, can be monitored in real time by monitoring the pressure drop. This allows the filter to be changed at the right time, saving resources, avoiding downtime and ensuring production quality.

Advantages

- Compact transducer with linear characteristic curves and optional display

- Measuring accuracy between 1 % and 3 % FS depending on the version

- Individual, also asymmetrical measuring ranges up to ± 50 Pa

High-end transmitter

for demanding applications

The precise differential pressure transmitters in the P 26 and P 34 series fulfil the highest demands for measuring accuracy and stability, even in small pressure ranges. This means that pressure cascades in clean rooms or clean production zones, for example, can be continuously monitored - for consistently high production quality and reliable personal protection. Thanks to the inductive measuring principle, excellent long-term stability and optimum temperature behaviour are guaranteed. Even the smallest pressure deviations are recognised immediately. In combination with differential pressure transducers, the pressure transmitters can also be used for volume flow measurement.

Advantages

- High-precision transducers for the smallest measuring ranges of ± 10 Pa

- Measuring accuracy of 0.2 % or 0.5 % FS depending on version

- High overload safety due to built-in valve

- Integrated cyclical zero point correction for maximum long-term stability

- Extensive modular system of variants